How to maintain the conveyor chain?

Transportation and daily maintenance of plastic chain plates and conveyor belts:

During transportation and storage, the conveyor belt should be kept clean and avoid direct sunlight or rain and snow, prevent contact with acids, alkalis, oils, organic solvents and other substances, and be one meter away from heating devices; 2. 3. 4. 5. 6.

During storage, the warehouse temperature should be maintained between 18-40 ℃, and the relative humidity should be maintained between 50-80%;

During storage, the product must be placed in rolls and must not be folded. It should be turned over once a season during storage;

Conveyor belts of different types and specifications should not be connected together for use, and their joints are often glued;

The type, structure, specification and number of layers of the conveyor belt should be reasonably selected according to the conditions of use;

The running speed of the conveyor belt should generally not be greater than 2.5 m/s. The materials with large block size and high abrasiveness and the unloading device using fixed pears should be operated at a low speed as much as possible;

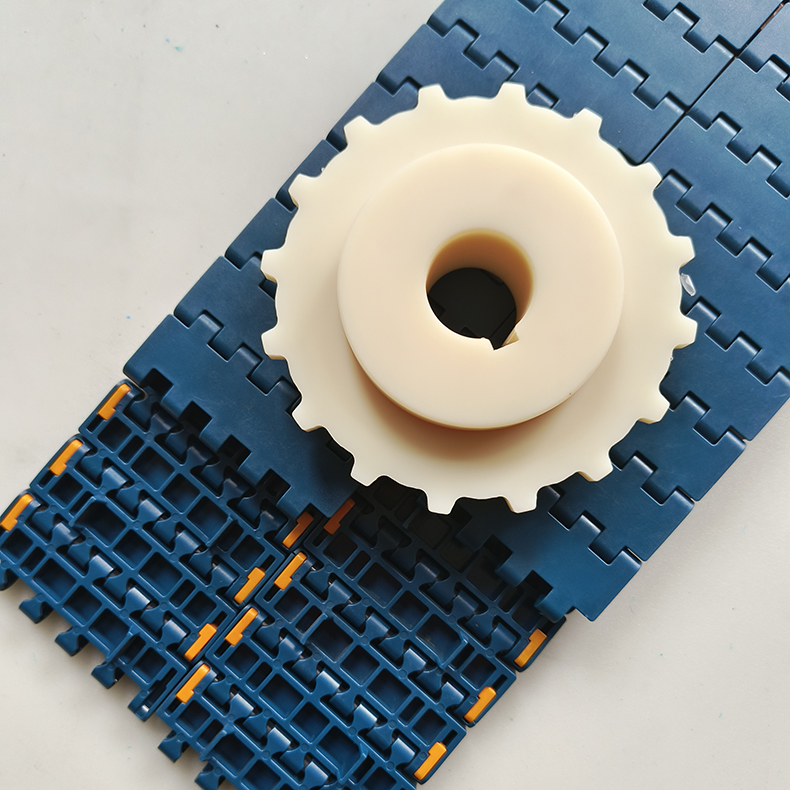

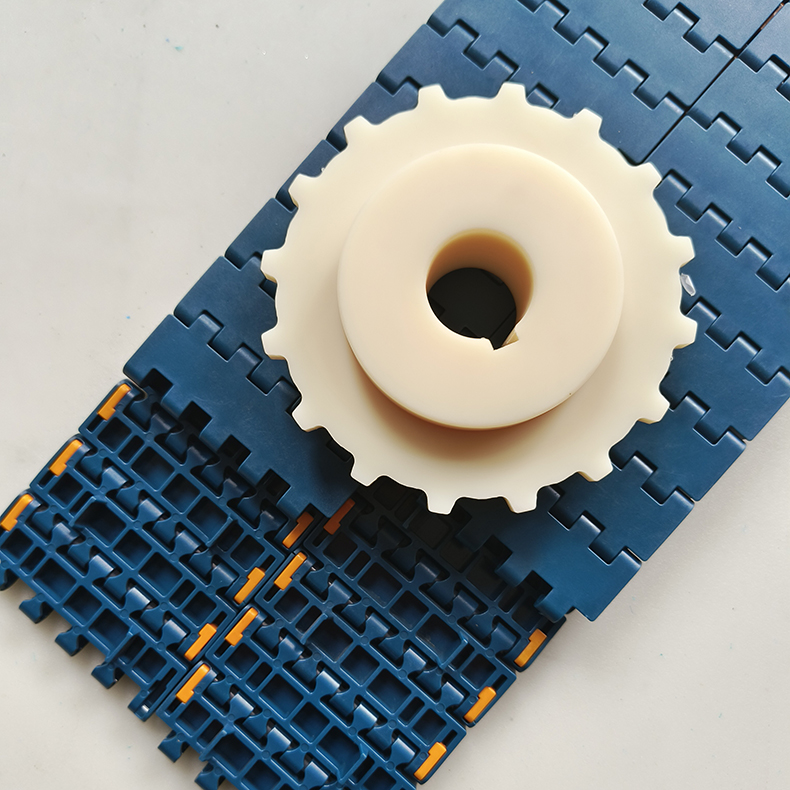

The relationship between the diameter of the conveyor's drive roller and the conveyor belt cloth layer, the matching of the drive roller and the redirecting roller, and the requirements for the roller groove angle should be reasonably selected according to the design regulations of the conveyor;

The feeding direction should be in the direction of the belt. In order to reduce the impact of the material on the belt when it falls, a chute should be used to reduce the distance the material falls; the distance between the rollers should be shortened and buffer rollers should be used to prevent leakage. The belt should be soft and moderately baffled to prevent the baffle from being too hard and scratching the surface of the conveyor belt;

The following matters should be noted when using the conveyor belt:

① Avoid covering the rollers with materials, causing poor rotation, prevent leakage from being stuck between the rollers and the belt, and pay attention to the lubrication of the moving parts;

② But the conveyor belt must not be oiled;

③ Avoid starting with load;

④ If the belt deviates, take measures to correct it when it is used;

⑤ If the belt is found to be partially damaged, repair it when it is used to avoid expansion;

How to avoid dryness when flex

How to avoid dryness when flex

How to maintain the conveyor c

How to maintain the conveyor c

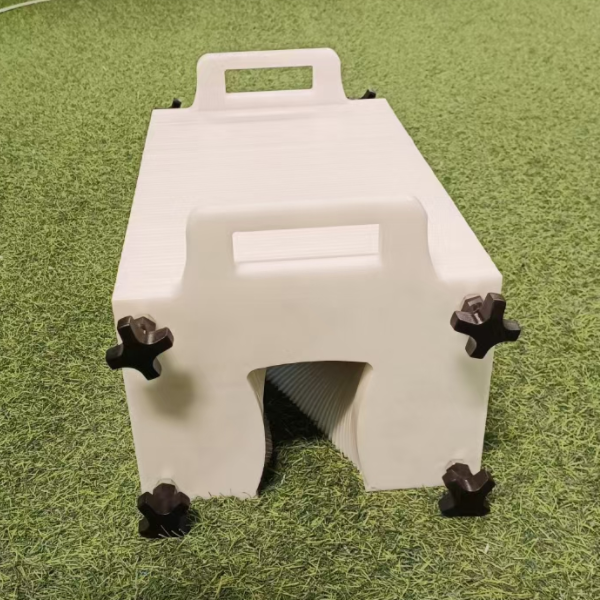

How the bottle flipper works?

How the bottle flipper works?

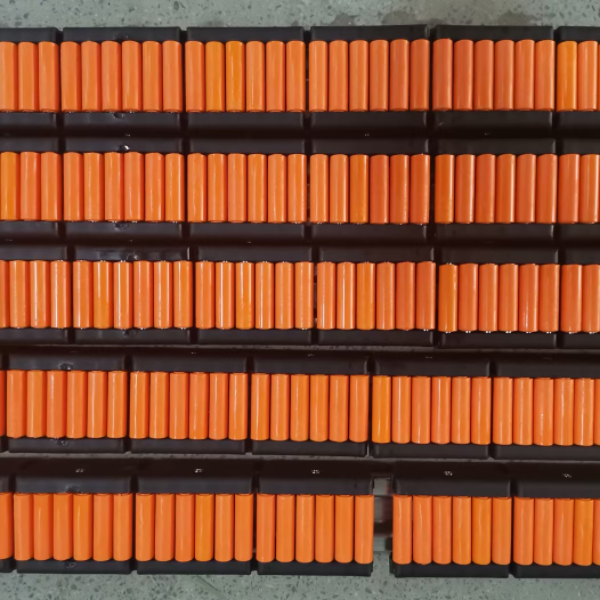

The main function of the rolle

The main function of the rolle