How the bottle flipper works?

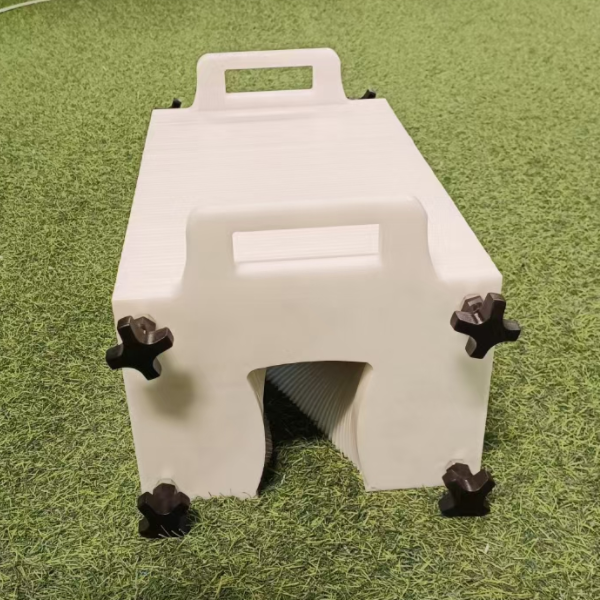

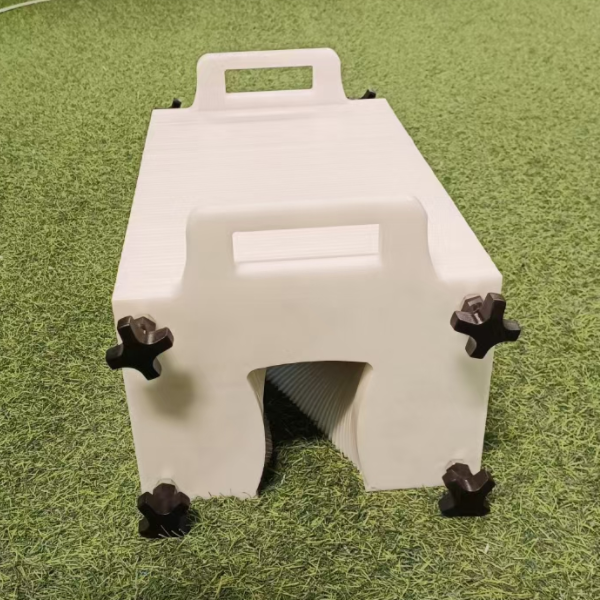

The bottle flipper has a simple structure and is equipped with a spiral inner cavity. The bottle flipper sends the bottle or can into the spiral inner cavity through a conveyor belt, so that the bottle or can is turned to the required angle (generally, the required turning angle is 180° or 360°), which plays the role of turning the bottle or can.

It is mainly used for turning cans, glass bottles, and plastic bottles in the beverage, alcohol and other industries.

Advantages of bottle flipper:

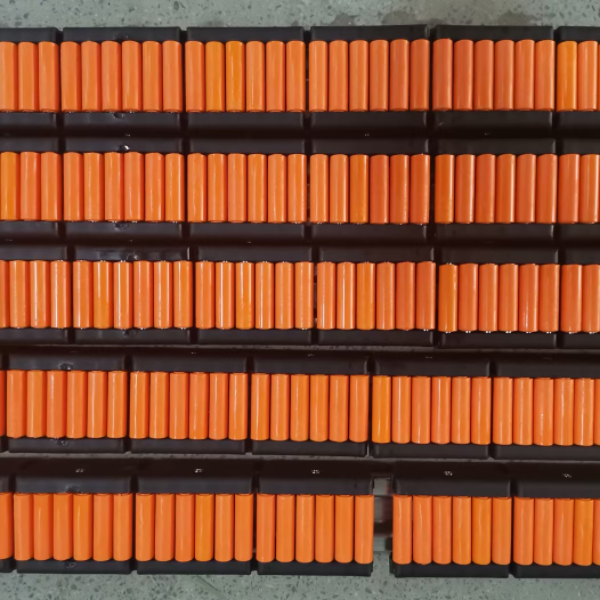

The traditional iron cage type can turner has a rough appearance, is easy to deform, and is easy to damage. It often scratches cans or bottles. The new bottle flipper uses 9 million molecular weight UPE material, which has a wear resistance that is 3 times that of ordinary can turners. It can self-lubricate, is easy to operate, highly wear-resistant, and has a long service life.

How to avoid dryness when flex

How to avoid dryness when flex

How to maintain the conveyor c

How to maintain the conveyor c

How the bottle flipper works?

How the bottle flipper works?

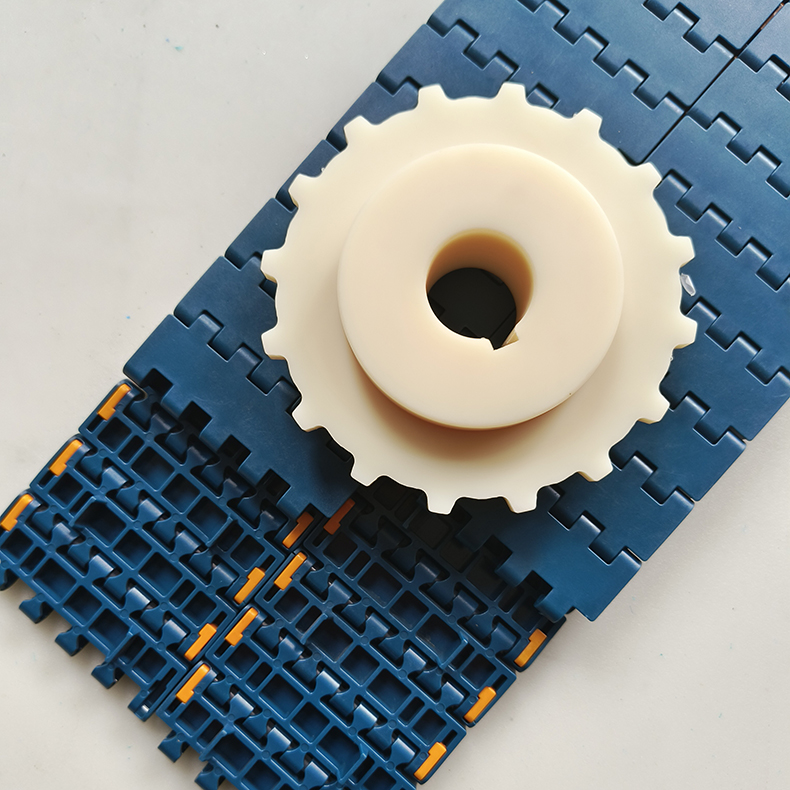

The main function of the rolle

The main function of the rolle