What are the advantages of chain conveyor lines?

What are the advantages of chain conveyor lines?

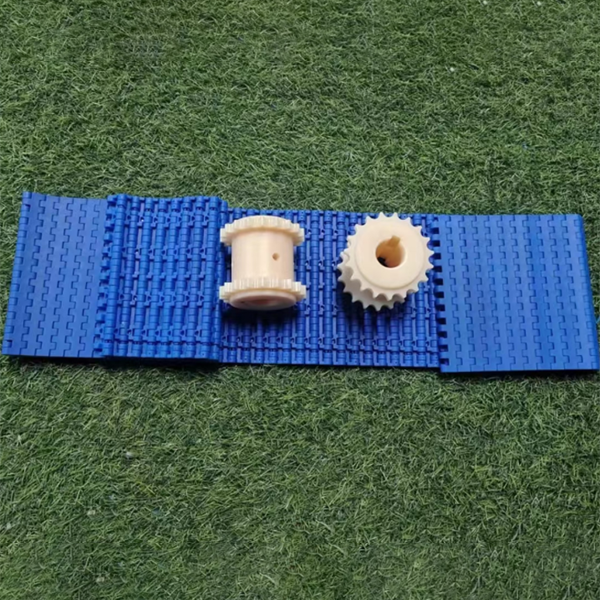

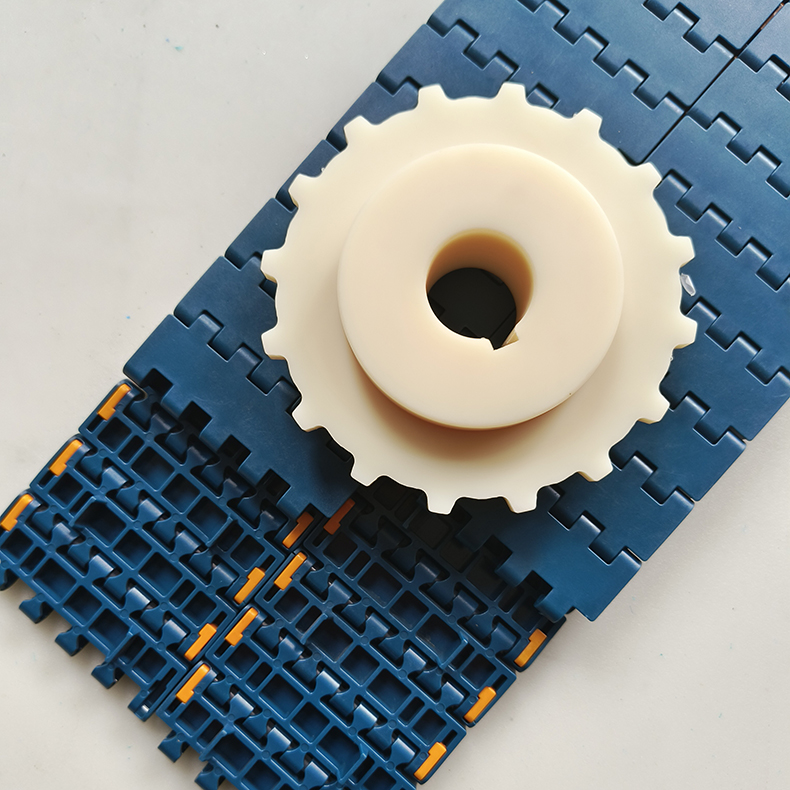

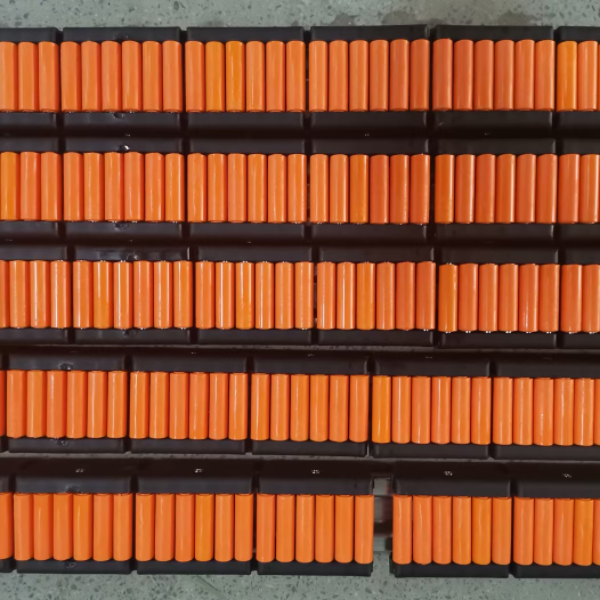

Adaptability and flexibility: Since the chain conveyor line uses a conveyor chain composed of chains and plates, it can be designed and customized according to different material characteristics and production requirements, so as to be suitable for conveying materials of various shapes, sizes and weights. Moreover, the chain conveyor line can carry out horizontal, vertical, oblique and other multi-directional material transportation according to the needs of the production line, and it has high flexibility and a wide range of use.

It has a large conveying capacity and stability: The chain conveyor line adopts chain transmission, can withstand large tension, and has strong conveying capacity. The chain conveyor line can use chain plates as conveying carriers, which can effectively prevent the dumping and scattering of materials, maintain the stable transportation of materials, and thus ensure the continuity and stability of the production process.

Long service life and low maintenance cost: The chain conveyor line is made of high-quality chain and plate materials, with a simple and strong structure, wear resistance, corrosion resistance, and a long service life. At the same time, the maintenance cost of the chain conveyor line is low. It only needs regular lubrication, inspection and individual wear parts to keep the equipment in good operating condition, and it also reduces the production cost to a certain extent.

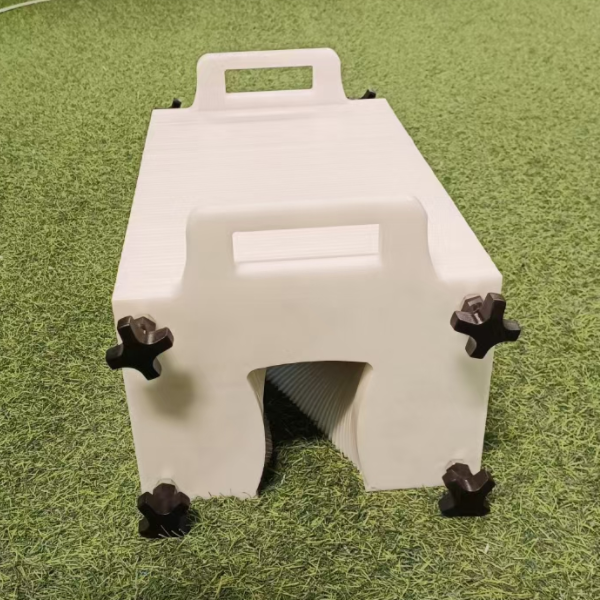

Safety and environmental protection: The chain conveyor line takes safety factors into consideration during design and manufacturing, and is equipped with multiple safety protection devices, such as limit switches and power-off protection, to ensure the safety and reliability of the equipment during operation. In addition, the chain conveyor line adopts a pollution-free conveying method, which meets environmental protection requirements and is conducive to the sustainable development of the enterprise.

How to avoid dryness when flex

How to avoid dryness when flex

How to maintain the conveyor c

How to maintain the conveyor c

How the bottle flipper works?

How the bottle flipper works?

The main function of the rolle

The main function of the rolle